The centrifugal casting process is a distinctive manufacturing technique used to create components and parts that are cylindrical by pouring molten materials into a rotating mold. The force generated by centrifugal forces in the process disperses the molten substance evenly creating high-quality and durable products. This method is extensively used in industries like aerospace, automotive, as well as metals to create pipes as well as bushings and bearings. Although it has many advantages however, it has some limitations. This article outlines the benefits and drawbacks of centrifugal casting in depth.

What is Centrifugal Casting?

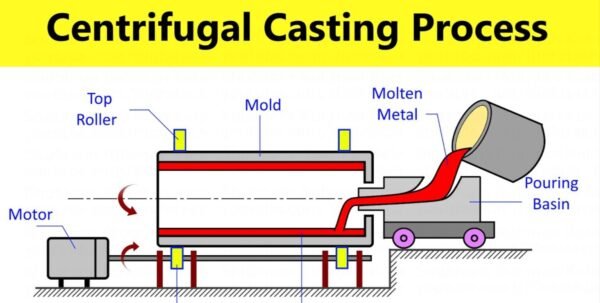

Centrifugal casting involves pouring hot metal into an elongated mold. As the mold spins high speed, the force of centrifugal forces the material to expand to create a solid and flawless component. The rotating process ensures an even distribution of the material and removes impurities. This makes this process perfect for making hollow and cylindrical components.

Advantages of Centrifugal Casting

- High-Quality Products

Centrifugal casting creates components that have superior mechanical properties. This process eliminates impurities, resulting in dense and non-defective products that have strong structural integrity. - Uniform Distribution

The force generated by the centrifugal force guarantees that the material is distributed evenly which results in uniform thickness and quality throughout the part. - Cost-Effectiveness

The process is highly efficient and requires little processing, which reduces material waste and manufacturing costs. In addition, reused molds reduce manufacturing costs. - Strength and Durability

Components that are made by centrifugal cast are stronger and more durable due to the removal of inclusions and porosity. - Versatility

This process is suited to many different materials, such as metals, alloys and composites. It can be used to create bushings, pipes, gears and cylinders. - Large-Scale Production

Centrifugal casting is perfect to produce large amounts of similar components, which ensures reliability and cost effectiveness in large-scale production. - Minimal Defects

The high speed of rotation and quick solidification eliminate gases pockets and shrinkage and other casting defects that are common. - Flexibility in Design

This technique permits the creation of complicated designs, like tapered or flanged parts by altering the mold’s design. - Improved Corrosion Resistance

Components produced by this method typically have superior finishes on their surfaces which increase its resistance against corrosion. - Environmental Benefits

The process helps reduce waste material and is therefore more eco green than other conventional casting techniques.

Disadvantages of Centrifugal Casting

- High Initial Costs

The cost of setting up for centrifugal casting tend to be expensive due to the requirement for molds and equipment that are specialized. - Limited to Rotational Symmetry

This technique is most suitable for symmetrical or cylindrical parts which limits its use to non-circular forms. - Material Restrictions

Although versatile, centrifugal cast is not suitable for some materials, specifically ones with low melt points or high levels of fluidity. - Complex Operation

The process demands skilled operators as well as exact control of parameters, like rotational speed and temperature to ensure the highest quality of output. - Mold Wear and Tear

The high speeds of rotation and thermal stress can result in an excessive wear and tear on molds, which can increase maintenance costs. - Inconsistent Internal Properties

The outer layers are usually solid and robust The inner layers could be slightly different due to the force centrifugal distribution. - Size Limitations

The size of the part is restricted by the capabilities of casting machinery as well as the mold, which limits its application to extremely large-scale projects. - Surface Finish Issues

While centrifugal casting can produce top-quality surfaces, additional processing may be needed for precise tolerances or for specific finishes. - Not Ideal for Small Quantities

The effectiveness of cost-effective centrifugal casting decreases for smaller production runs due to large initial setup costs and the equipment cost. - Safety Concerns

The high speed and melting of the material during the process create safety hazards, which require strict adherence to safety guidelines.

Comparison Table: Advantages vs. Disadvantages

| Advantages | Disadvantages |

|---|---|

| Produces high-quality, defect-free components | The initial setup costs are expensive. |

| Uniform material distribution | Limited to the symmetry of rotation |

| Cost-effective and minimal waste | Specific alloys have material restrictions |

| Superior strength and endurance | Needs an expert operating and precise supervision |

| Ideal for mass production | The wear and tear on mold increases maintenance |

| Eliminates the porosity and inclusions | Equipment capacity limits limit the size of equipment capacity |

| Supports complex designs | Additional machining to achieve specific finishes |

| Increased resistance to corrosion | It is less cost-effective for small production runs |

| A sustainable process | High speeds and melting metal |

Applications of Centrifugal Casting

- Automotive Industry: Making engine components, bushings and gears.

- Aerospace Industry: Manufacturing lightweight, high-strength tubes and cylinders.

- Oil and Gas Sector: Creating corrosion-resistant pipes to transport fluids.

- industrial equipment: Rollings, bearings and wear-resistant components.

- Energy Generation Parts used in turbines including casings and rings.

Best Practices in Centrifugal Casting

- Quality Mold Design Utilize high-quality molds to minimize wear and guarantee the same output.

- Parameter Control Control precisely temperature and speed to achieve the best outcomes.

- regular maintenance: Check and repair equipment regularly to avoid breakdowns and ensure security.

- Materials Selection Select the appropriate material according to the requirements of the process and application.

- Skilled Workforce Help operators learn how to deal with the complexity of the process in a way that is efficient.

Conclusion

Centrifugal casting is a highly efficient manufacturing process that provides a variety of advantages, such as superior quality products, low cost and design flexibility. The ability to create dense sturdy, robust, and free of defects components makes it an ideal choice for a wide range of industries. However, it also has some drawbacks like expensive initial costs as well as material limitations and the complexity of operation.

When weighing the benefits and disadvantages of the process, businesses can determine if centrifugal cast is in line with their particular requirements. If used correctly it can result in high-performance products that meet stringent industrial demands and is a useful instrument in modern manufacturing.